Services

Converting Services and Capabilities

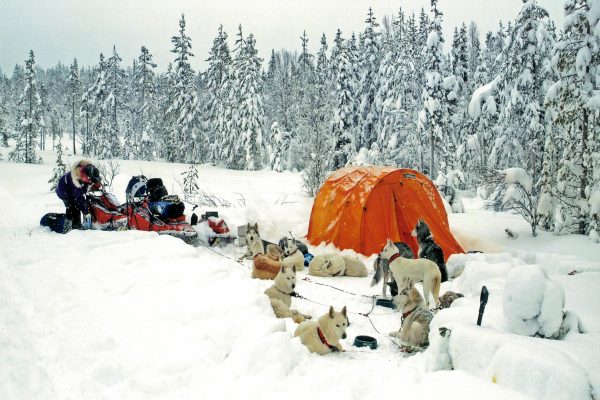

ANCI, inc. has the capabilities to help engineer and manufacture new and innovative composite materials through its variety of manufacturing capabilities. We work side by side with engineers to develop innovative materials for various applications and markets ranging from medical equipment to high-performance fabrics for racing sails and arctic tents.

Combining Possibilities

Applications for different composite materials manufactured through different lamination types are never-ending. Whether it be for added reinforcement or to make the perfect product composite materials made with ANCI guarantee a quality end product.

Thermal Lamination creates composites with at least one low melt component.

Thermal Lamination creates composites with at least one low melt component.

Benefits of laminating composites thermally include high lamination strength properties without the use of adhesives.

This provides a smoother finish with an exceptionally strong bond.

Our powder lamination process uses a variety of powder adhesives to provide a

great bond to combine dissimilar materials into a smooth and strong composite.

The benefit of using powder lamination as opposed to other lamination types is because small amounts of powder can be used, resulting in a softer and less stiff composite. This process is also done at lower melting temperatures for cases that require less heat.

Sonic bonding uses ultrasonic sound waves to bond different materials together at each individual focused point, eliminating the risk of losing the integrity of the material properties.

material properties.

In this process, no heat or adhesives are used and making it a viable option to combine dissimilar materials or materials with different melting points. Overall, ultrasonic bonding provides optimal bond strength for many composite applications.

Composite Applications

Packaging solutions

Filtration composites

Building wraps / underlayments

Weed block fabric

Car covers

Pond / Aquaculture liners

Industrial padded fabric

High-performance composites

and more…